Rear Hoop Legs

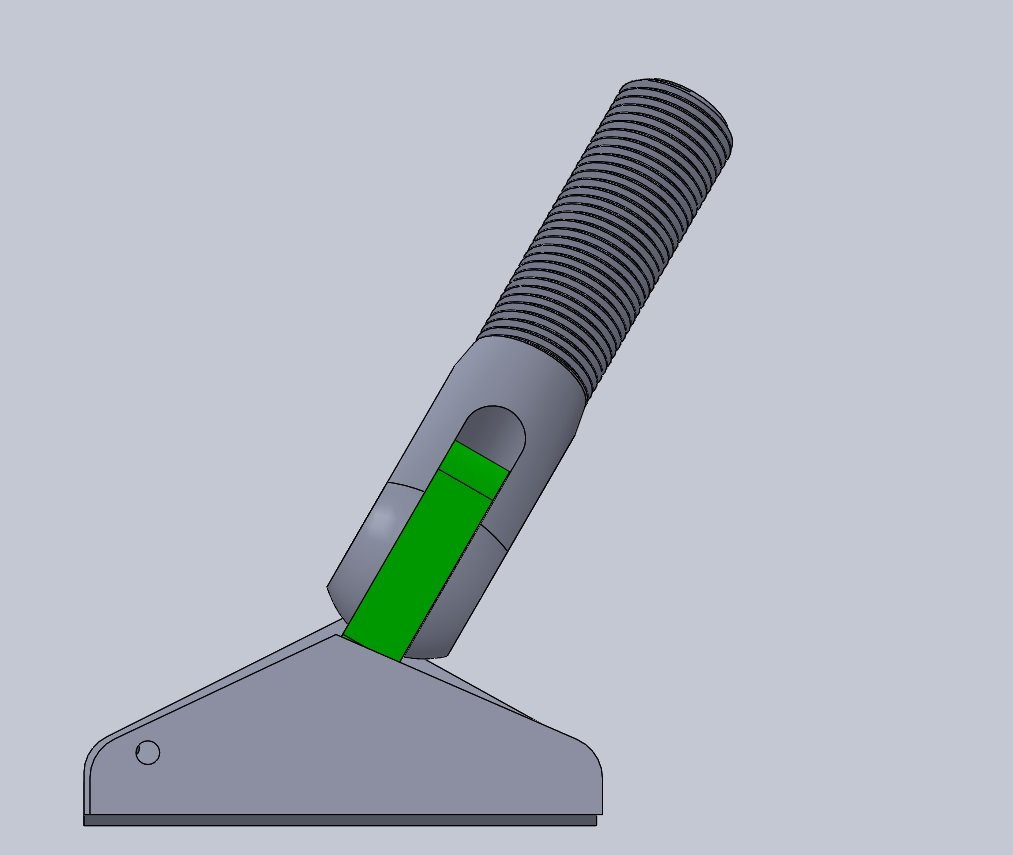

Bottom joint is a 3/4”-16 left-hand threaded grade 8 bolt with the head cut off. At this point, I’m using two jamb nuts, but I’m wondering if I should weld the bolt to the lower section.

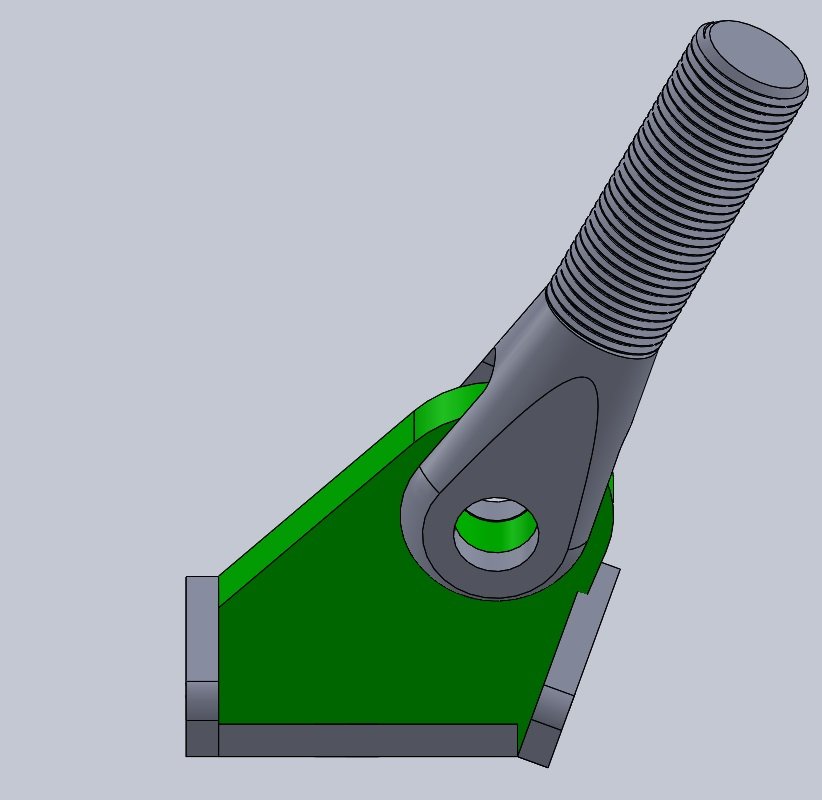

The top is mild steel 3/4”-16 slot clevis. The bracket is a 3D-printed prototype. The tab that engages the slot is 3/8”, the back plate is 1/4” and the gussets are 0.190”. If I go with SendCutSend the 3/8” will be hot rolled, but the rest can be 4130 (there might be another company that can do the 3/8” in 4130). The tab tilts down and is at a 60-degree angle from the firewall, the clvis hole is offset from the centner of the bracket and the outer gusset is on an angle. It will be a bit fussy to weld and will need to be hard tacked in place and then welded on bench. Care will need to be taken not to warp things while welding. The edge of the tab will need to be milled at 60 degrees. I’m thinking about adding a tab to the 3/8” piece, but the slot in the base plate needs to be at 60-degrees. I could laser cut a small slot and try to file the part or I could buy a cheap tilting vice and attempt to achieve the angle with an end mill. I’ll also have to tweak some of the other pieces given the angles involved.

The must be inserted from the bottom which doesn’t thrill me. The tab can’t be oriented vertically due to the chassis mounting bolts. I could tilt the tab on a 45-degreed (i.e., in between horizontal and vertical which would allow the bolt to inserted downward on 45 degree angle, but then I have to fabricate a complex compound angle.

I could have it CNC’d but the brackets are handed and that’s a bit pricy and takes a while.

Another option would be to go with a rod end and have the bolt insert sideways like Fran does. The difference is that it would be 3/4” high misalignment (if it fit) ears would be at the correct angle and no spacers would be required.