Garage

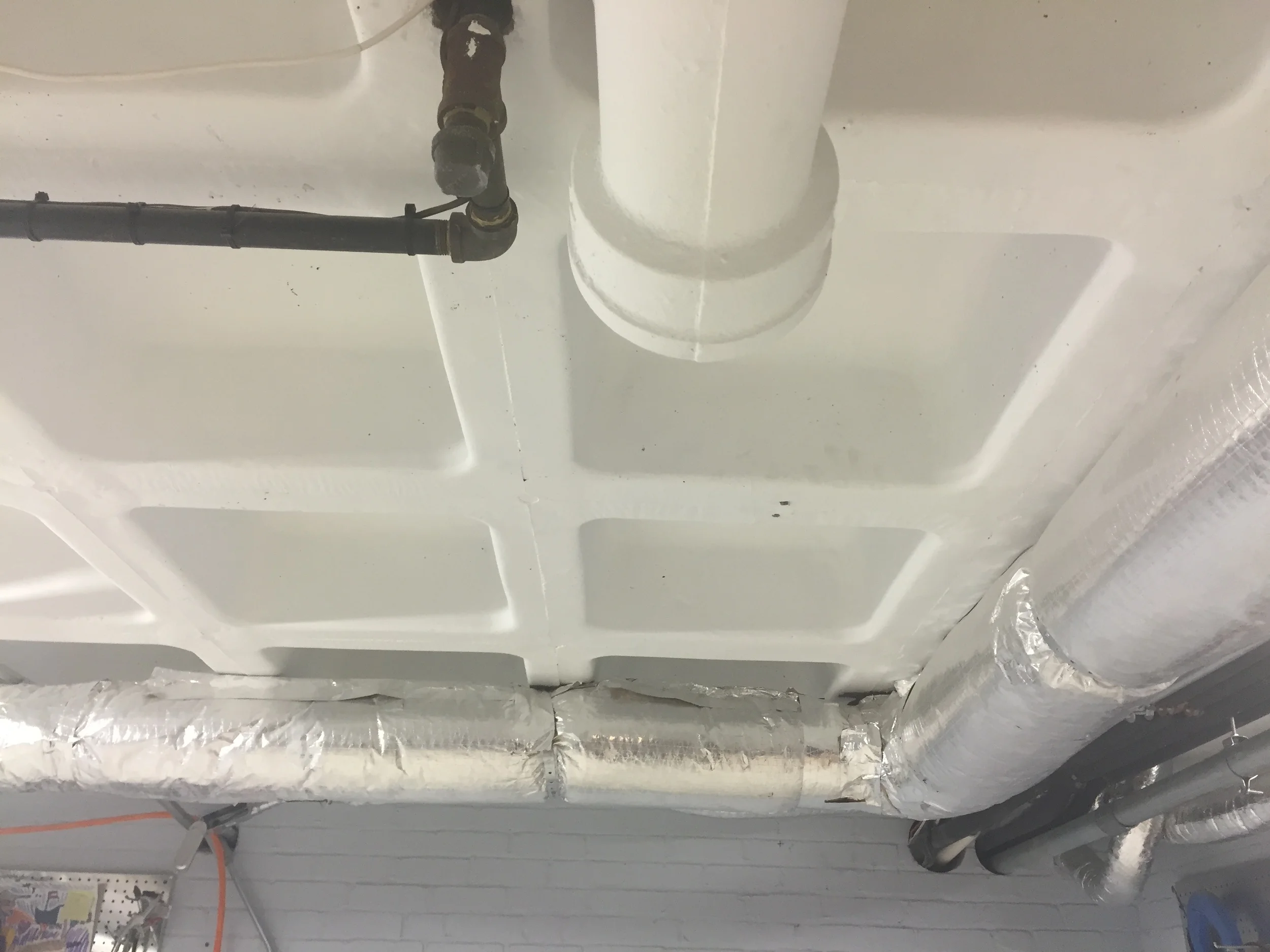

Before building the cars I needed to redo the garage – specifically level the floor and install a flush mount car lift. The house was built in the 1920’s by a commercial architect for himself and it’s built like a brick you know what. The ceiling is a concrete waffle slab, the exterior walls are 12” solid concrete and the interior walls are bricked two courses wide.

Concrete Bomb

With a ceiling like that, I should have known that the floor wouldn't be easy to remove. It was nearly 8" thick and had1/2" and 3/4" rebar in it.

What I wasn’t expecting were two interior foundation walls that go down below the frost line (see below). The guy who built the house did everything beyond overkill! Since I’m re-grading the floor, they will need to be reduced.

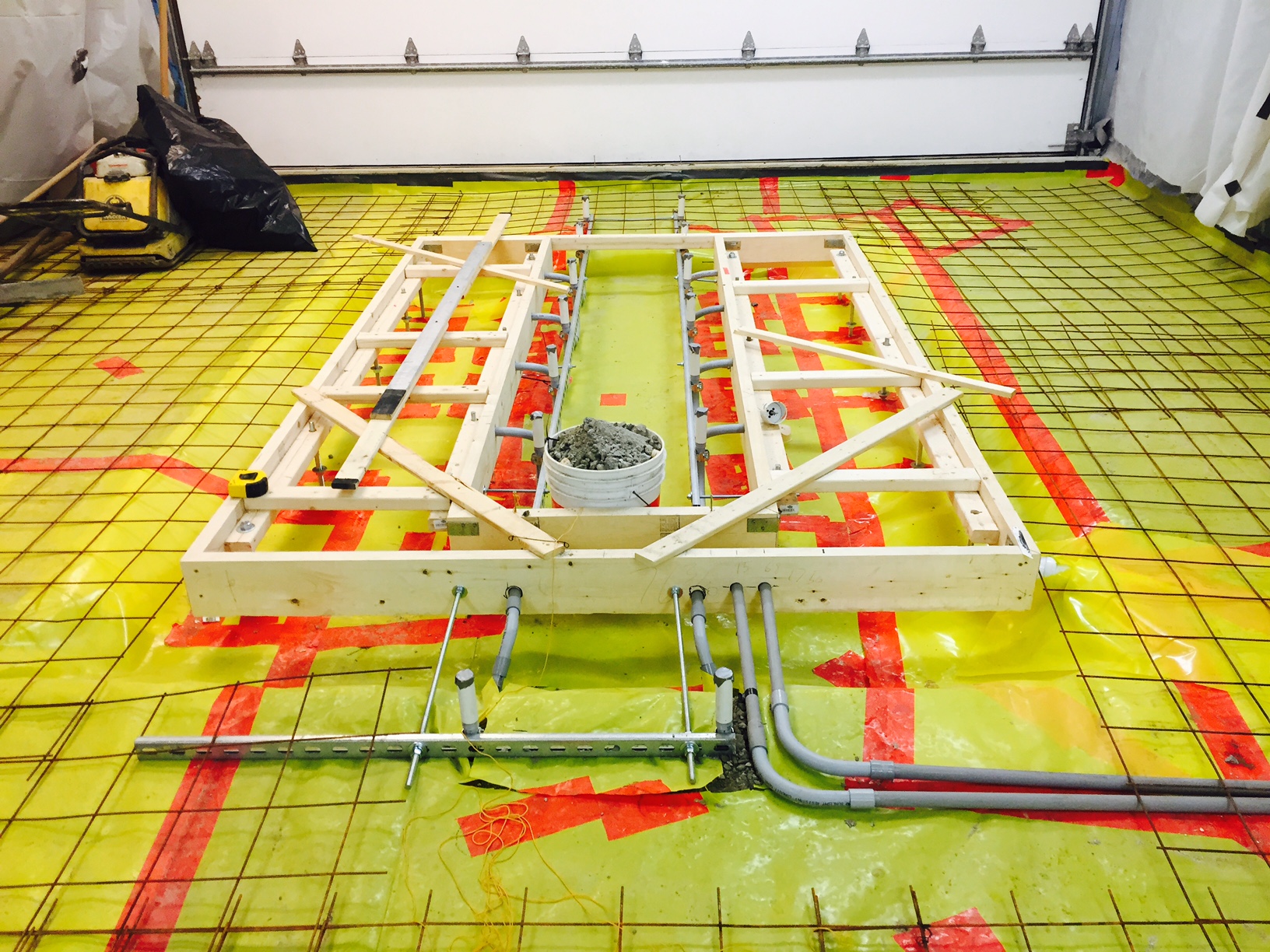

The floor has been graded and compacted with gravel/stone dust mix. The pit is in place with two concrete pads to receive ¾” stainless rod that will support the form. Concrete was also used to maintain a 45 degree slope from the floor to the bottom of the pit. This will keep the edges from crumbling when people are walking on it during the pour.

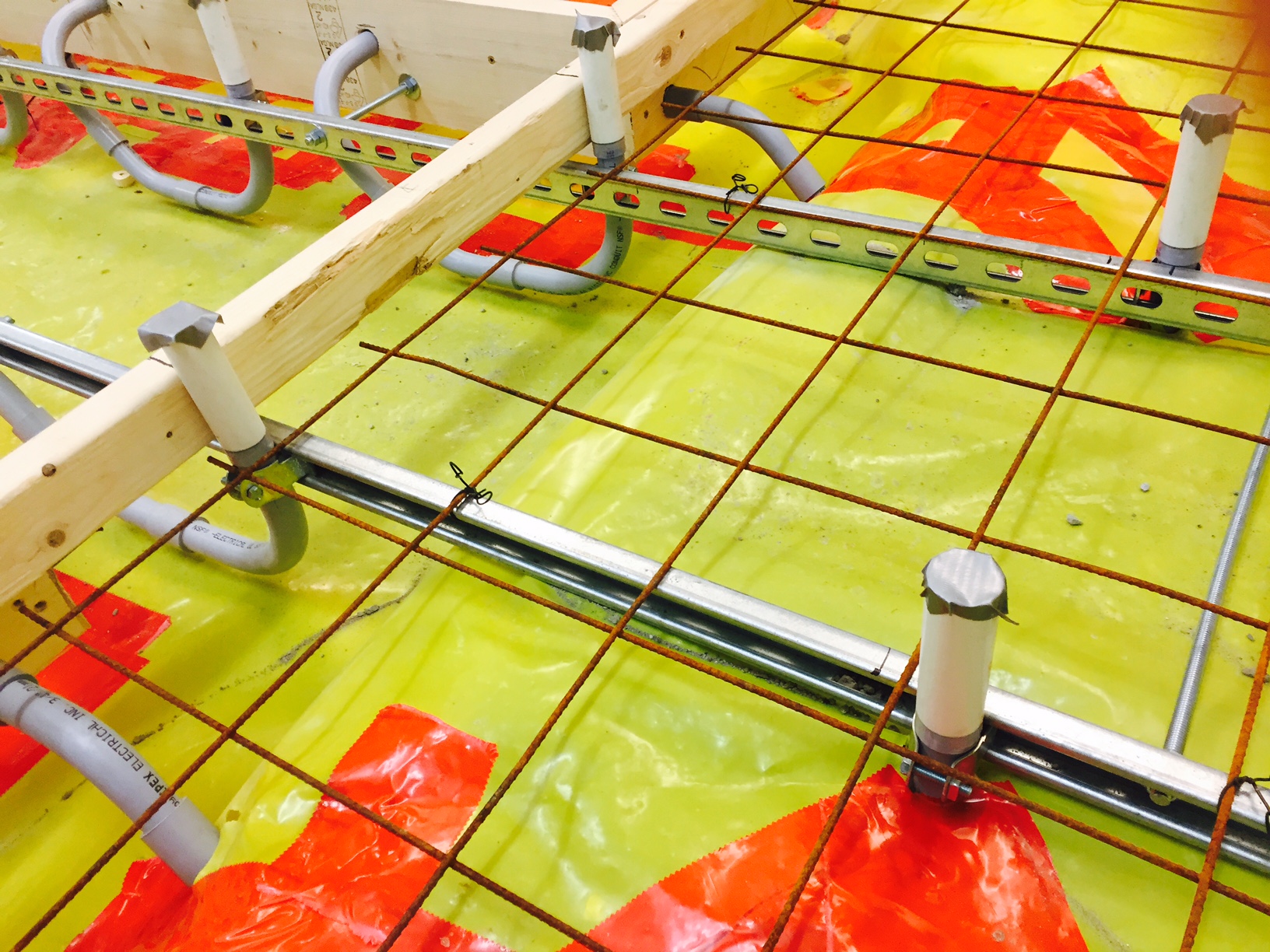

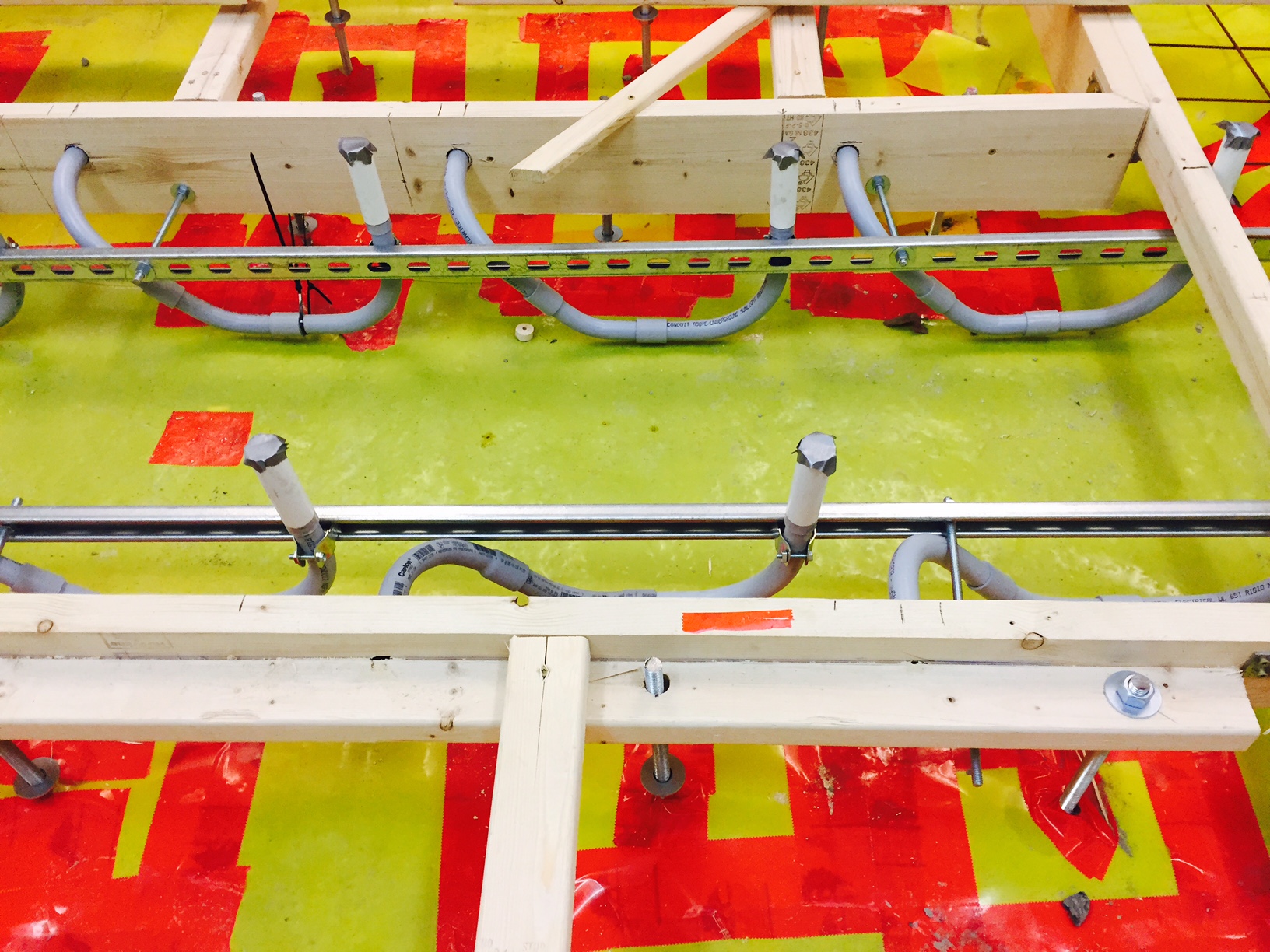

The seams in the membrane were sealed with a special red tape. A form was built and mounted to the stainless steel rods epoxied into the previously poured concrete. Using nuts on the rods the form was leveled to within 1/16” of an inch. Even with multiple people standing on it, it didn’t budge. Rod penetrations were taped and then further sealed with liquid membrane.

I decided to add 14 very small flush mount LED lights from Deck Dots under the lift. You can see the conduit in the middle of the pit. Unistrut was used to ensure nothing moved during the pour. I wound up speaking with the Deck Dots owner, a nice guy with cool products. After some discussion he was good enough to ship me his next-gen version before they officially shipped.

A door leading into a storage room was created in a brick wall. Previously I had to walk through the home theater and boiler room to get there, so this is quite an improvement.

Nothing like a little snow to delay things...

The floor pour...

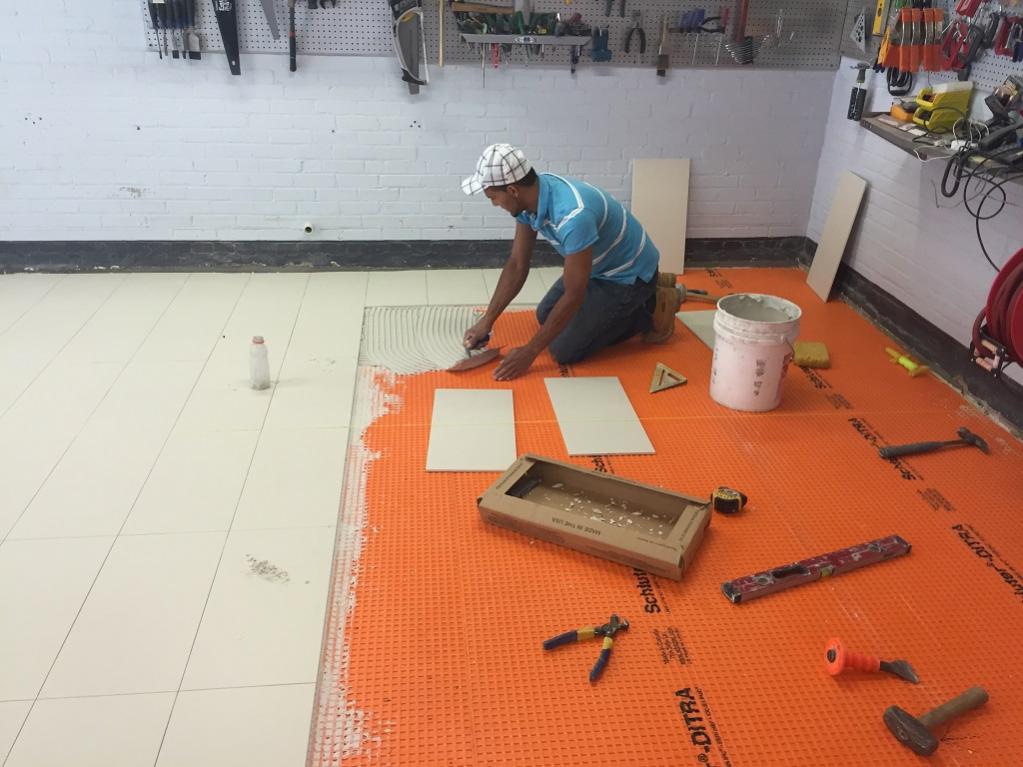

The lift has been installed. I decided to go with 12” x 24” porcelain tiles (Iris Deluxe Perla Honed). A Schluter DITRA uncoupling membrane was installed over the entire floor and the tile was installed with 1/16” spacing and epoxy grout. The LED floor lights have O-rings that hold it in place and provide a water-tight seal.

Do I get to keep my man card if I get as excited about garage cabinets as my wife gets about kitchen cabinets? Lista cabinets can hold 440 lbs/drawer... yeah, my man card is safe. They're made in Holliston MA which is a short drive from my location.

A little help from Connor installing SwissTrax flooring...

This was one of those do and ask for forgiveness later things (forgiveness has yet to be granted). Never has a piece of porcelain created so much controversy. I just don't get it. We've had a bidet in the master bedroom for over a decade, but somehow a urinal in the boiler room is weird. I guess it's like the double standard with toilet seats. They go both up and down but it seems that women can't put them down. Hey wait, doesn't this ingenious device actually solve that problem?

Finished the boiler room...

Custom cover for the lift's balance bar.

The plastics bins from Shaller are great to keep parts and tools organized. The picture below is the SAE 18-8 stainless fasteners. There is another full size drawer for metric -- I sure as hell wish we had converted to metric. The neat labels on white paper were done by my daughter. I need her to finish the rest of drawers.

The 2" drawers provide an efficient way to layout tools.

The Quincy air compressor has an industrial-duty Baldor motor made in the USA. It's been set up with an automatic moisture purge. The air is distributed via a RapidPipe aluminum tube distribution system from RapidAir. The aluminum version is much better than the plastic version because it cools the air enough to help it condense which limits the amount of water that the downstream water filters need to deal with. It uses o-rings which apparently do a very good job. I have turned the compressor off before a two-week trip and when I returned the pipes still had pressure. The safety air couplers from Provost are also really nice to use.

It's not done, but I've got the cobra in and was able to do some work on the M5.