SL-C Engine

“If you can leave two black stripes from the exit of one corner to the braking zone of the next, you have enough horsepower.”

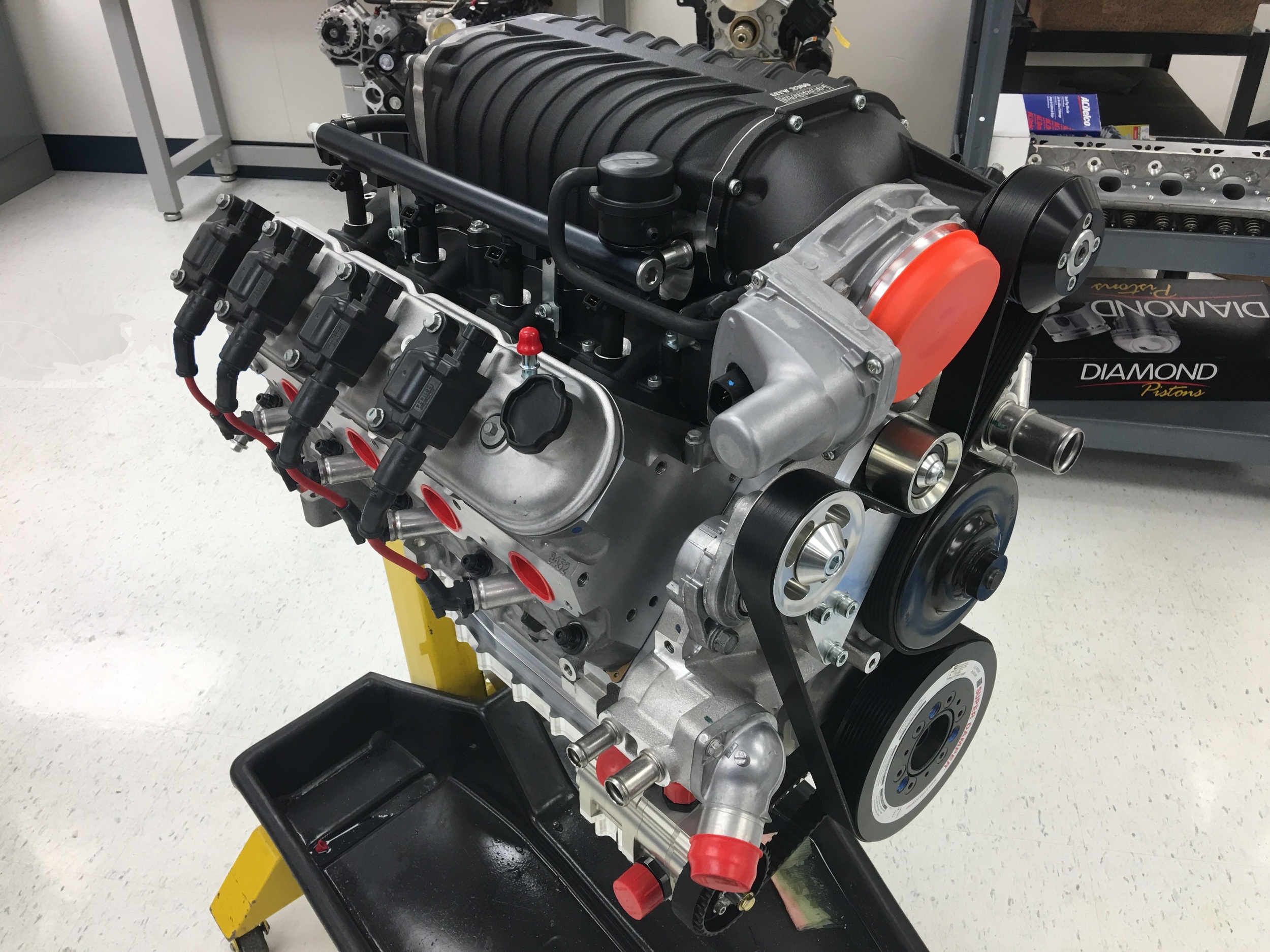

The SL-C deserves a special engine. I spent time investigating Ferrari, Lamborghini and Audi A8 V10 engines. In the end I choose American iron (well, aluminum actually)... a supercharged LS7 built by esteemed engine guru Brian Thompson.

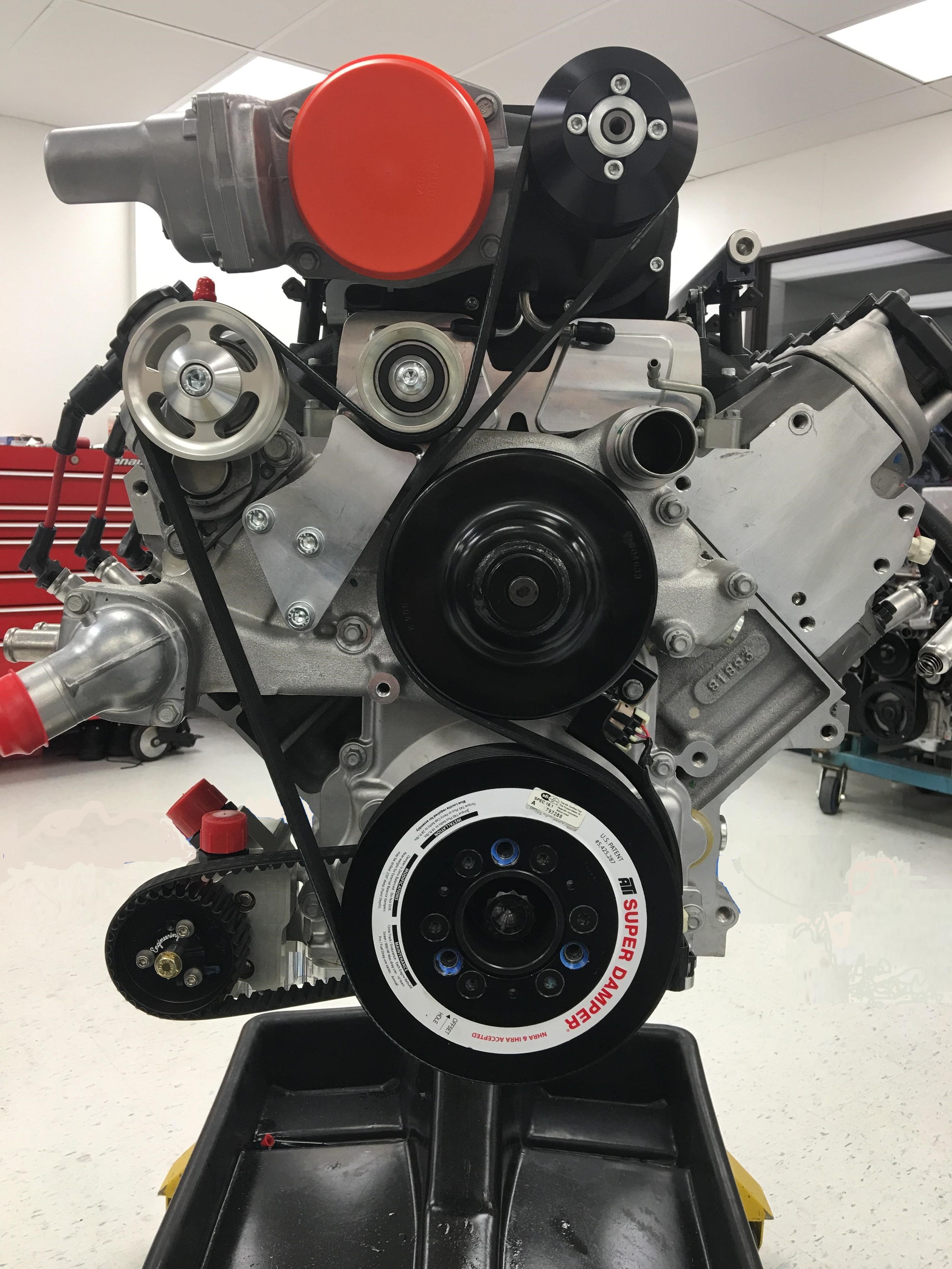

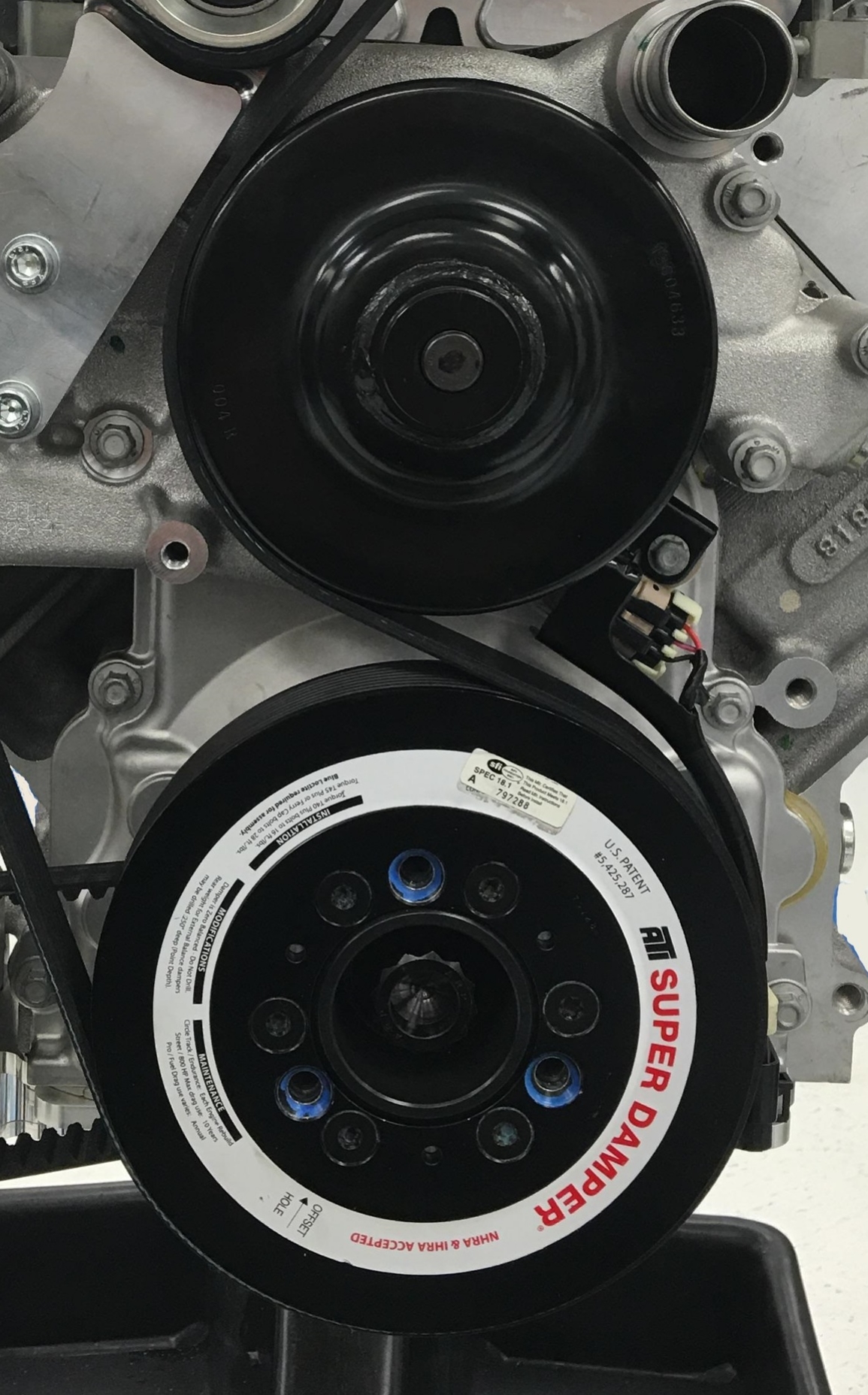

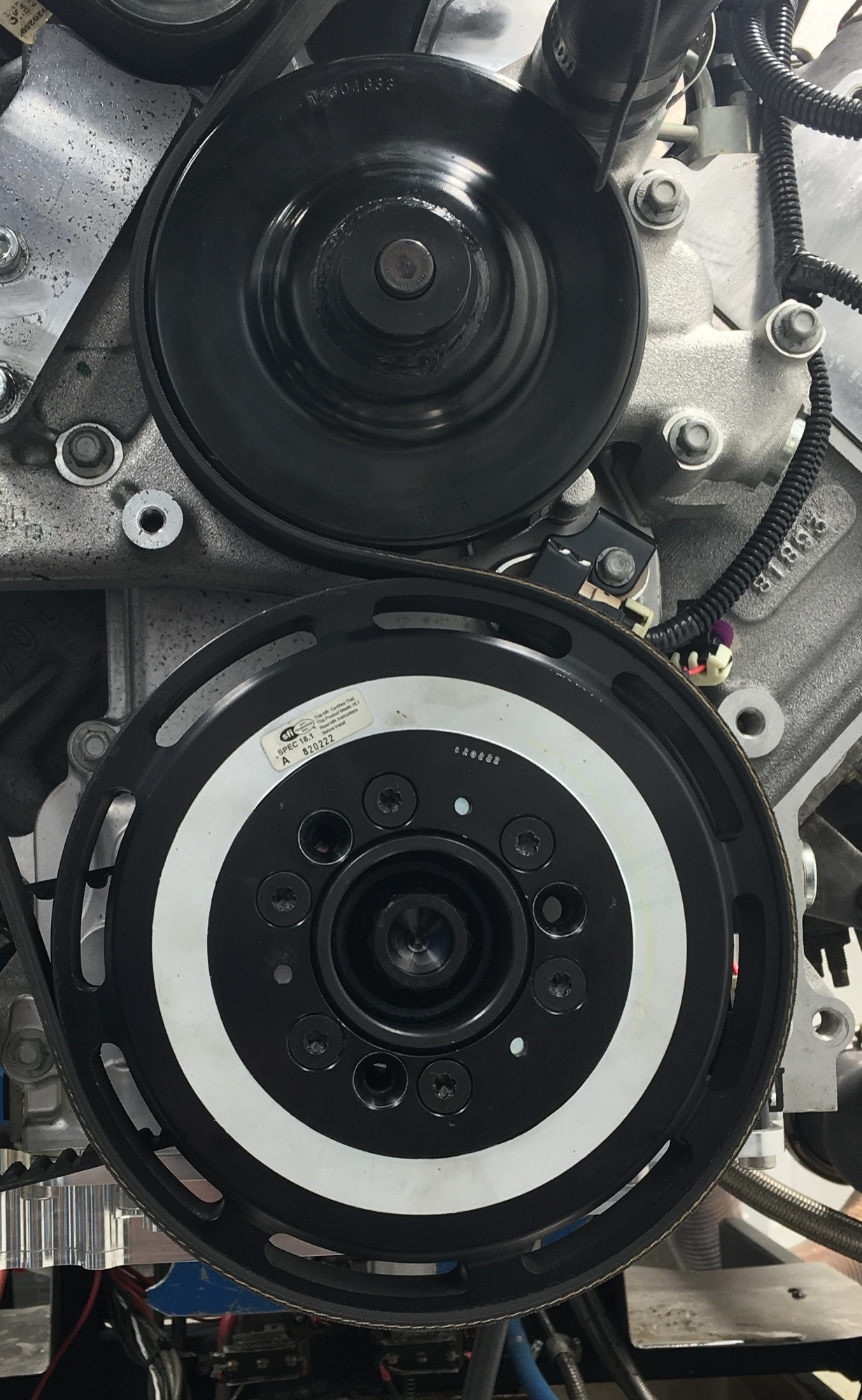

The belt shown above is a Gates K080653; 8 ribs, top width 1.087", outside circumference 65.922". They have a belt chart here. I have no documented ATI part numbers and according to ATI I would have to disassemble everything to gain access to their part numbers That #@(@!&! drives me nuts. After some back in forth with ATI they're pretty sure that I have a 916033A hub, with a standard Chevy big block 3.2" bolt circle and recess with a 2.050" ID.

This configuration has three problems: there is no provision for an alternator or an A/C compressor, the belt starts to slip a little before 900 HP and I’m going to replace the mechanical water pump with an electrical one. The plan is create three separate planes in front of the engine to drive the accessories:

Plane 1: Oil pump running on a cog belt and AN cooling lines

Plane 2: Damper and supercharger running on l be a cog belt or a 8-rib serpentine belt

Plane 3: Alternator and A/C compressor running on an 6-rib serpentine belt

Front dress

Supercharger: Harrop HTV 2300 or LS-Series FDFI …

| Qty. | Part Number | Description | Unit Price | Ext. Price |

|---|---|---|---|---|

| 1 | n/a | Thompson Automotive Custom-Built Supercharged LS7 Engine | $44,000.00 | $44,000.00 |

| 1 | 917094 | ATI Super Damper Shell Assembly, 6% Overdrive, 10-Grooves | $363.04 | $363.04 |

| 1 | 950220 | Damper Bolt Pack; 5/16"-18 x 1" (Package of 6) | $7.95 | $7.95 |

| 3 | 951450 | Bolt 3/8"-16 x 1-1/2", CBS Counterbore | $1.87 | $5.61 |

| Total | $44,376.60 |

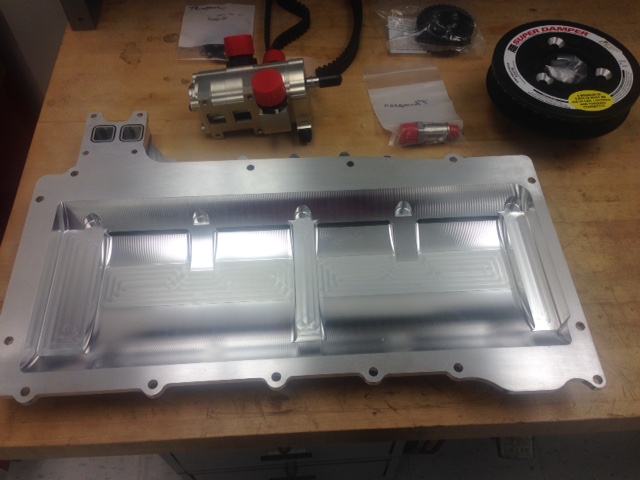

Oil Pan

A great engine deserves a great oiling system so a three-stage Daily Engineering dry sump was added. These things are works of art. They are CNC machined from billet 6061 T6 aluminum. The oil pump bolts directly to the oil pan which eliminates the A/N lines between the oil pump and oil pan. All scavenge lines are internally machined into the oil pan eliminating the costly weight and expense of external scavenge A/N lines.

Notes

Dyno Run

When we added the Daily pan we had to change around the pulleys which meant that we weren't able to spin the supercharger as fast as we wanted. So for the second run we added a slightly bigger crankshaft pulley. If you compare the lower pulley in the pictures below you will note that the one on the right which was used for the second run is slightly larger which increased boost. This small change generated an increase of almost 100 HP. The amount of boost can be changed by varying the size of the crankshaft and/or supercharger pulley. The great thing about forced induction is that if you increase the boost you get more power so long as the engine can take it – and this engine can take it.

With the pulleys on hand we were only able to achieve 10.5 psi of boost rather than the 17 psi max. We also didn't spend much time tuning because the dyno was set up for a GM E67 ECU and the car will have a MoTeC setup. However, we still achieved some very respectable numbers: 842 HP and 818 lb-ft. With the proper pulleys this engine will produce 1000 HP. Note that in the videos below the engine looks a lot messier than the pictures above because the wiring harness, cooling lines etc. are all temporary.

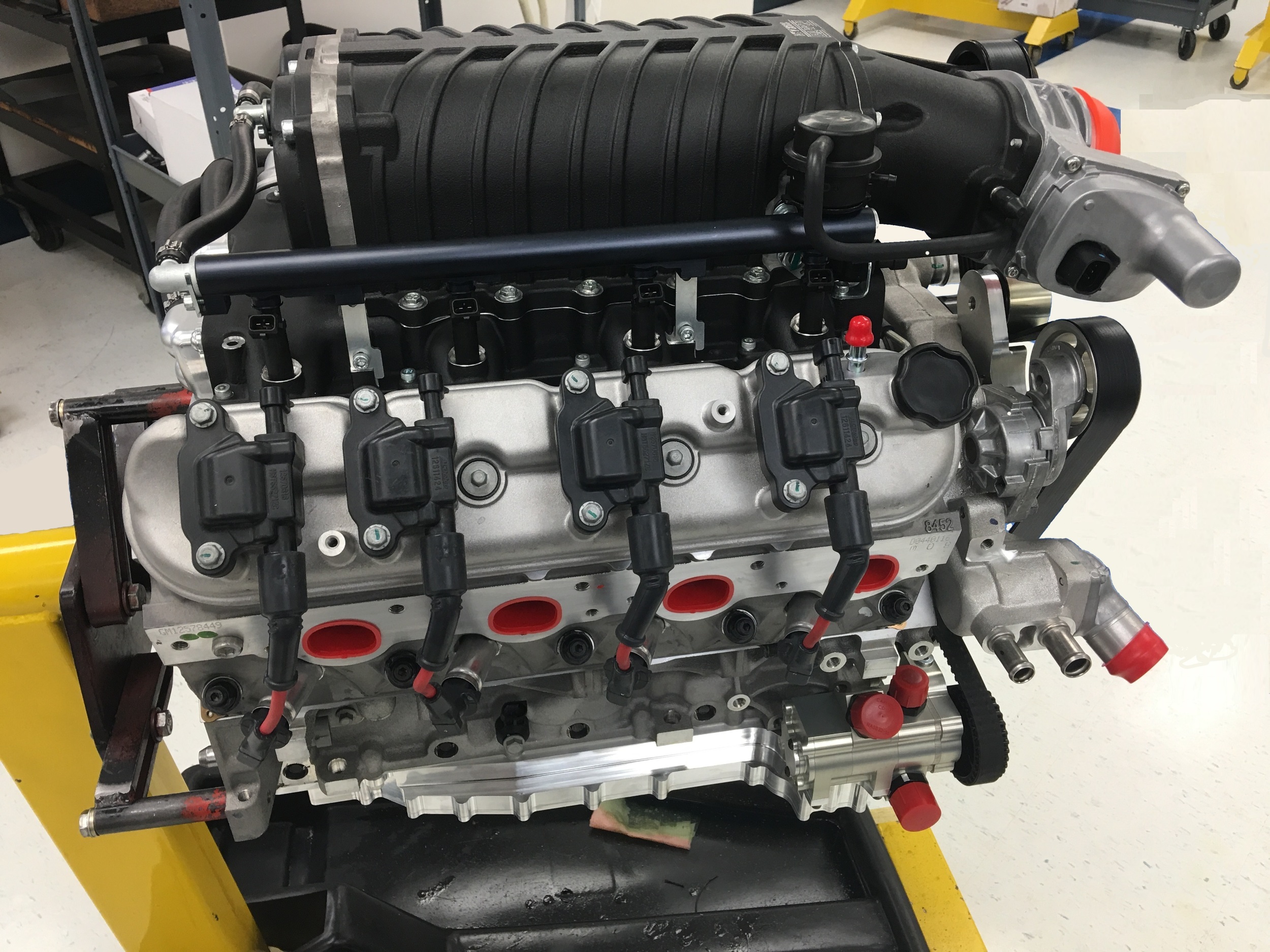

SPEC SHEET: LS7 SC 427 CI

Bore: 04.130"

Stroke: 4.000"

Displacement: 427ci/7.0L

Redline: 7,000 RPM

Horsepower: TBD hp

Torque: TBD lb-ft

CR: 9.0

Block: LS7 Aluminum (ARP main studs)

Crankshaft: Callies Dragon Slayer 4340 forged steel with ATI Super Damper

Connecting Rods: Oliver 4340 billet steel 6.125

Pistons: Diamond 2618 forged

Wrist Pins: .927 tool steel

Camshaft: Lingenfelter/COMP GT22

Cylinder Heads: CNC-ported LS7

lntake Valves: Del West titanium 2.205" diameter

Exhaust Valves: Ferrea 1.615" diameter

Springs: PAC titanium retainers and seals

lnduction: Harrop HTV 2300

Oiling System: Dailey 3-stage dry sump

Build Sheets

The block was purchased new and never had a VIN. There should be a serial number on the left side near the bell housing bolts. Brian and his crew provided the following build sheets:

Parts

Engine mount brackets; 3/8" x 2.3" shank

Suspension: 1.5" grip, 2.25+ length, 1/2-20

| Qty. | Part Number | Description | Unit Price |

|---|---|---|---|

| 1 | 99-AKIT12279 | Harrop Engine Cover Supercharger FDFI Series | $454.00 |