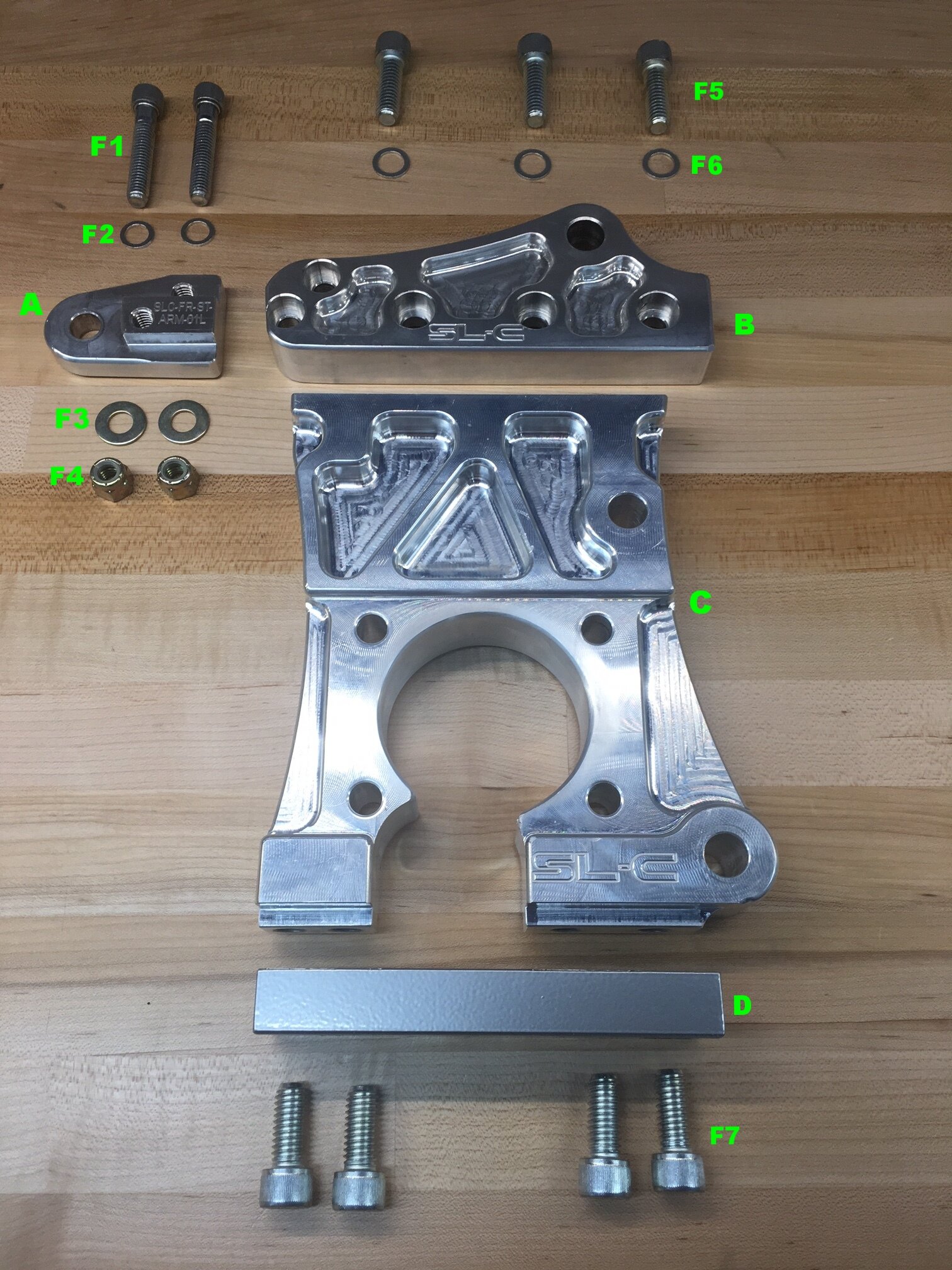

Maintenance - Front Uprights

| ID | Left Side | Right Side | Description | Material |

|---|---|---|---|---|

| A | SLC-FR-ST-ARM-01L | SLC-FR-ST-ARM-01R | Steering Arm | Aluminum |

| B | SLC-FR-TP-01L | SLC-FR-TP-01R | Upright Top | Aluminum |

| C | SLCFRLBJP | Same* | Upright | Aluminum |

| D | SLCRRLBJP | Same | Lower Ball Joint Plate | Steel |

***Note that when I machined the uprights for the improved wheel hubs a small chamfer was added to the outside edge of the upright, so my uprights are handed.

| ID | Qty. | Description | Compound | Torque(Foot-Pounds) | Tool |

|---|---|---|---|---|---|

| F1 | 2 | 3/8"-16 x 2" Socket Head Cap Screw | Anti-Seize* | ??? | 5/16" Hex Bit Socket |

| F2 | 2 | 3/8" Socket Cap Washer | - | - | - |

| F3 | 2 | 3/8" Washer (Grade 8) | - | - | - |

| F4 | 2 | 3/8" Nyloc (Grade 8) | - | ??? | 9/16" Socket |

| F5 | 3 | 7/16"-14 x 1-1/4" Socket Head Cap Screw | Anti-Seize | ??? | 3/8" Hex Bit Socket |

| F6 | 3 | 7/16" Socket Cap Washer | - | - | - |

| F7 | 4 | 7/16"-14 x 2" Socket Head Cap Screw | Anti-Seize | ??? | 3/8" Hex Bit Socket |

| F8 | 1 | 1/2"-20 x 2-1/8" Long Grip AN Bolt | - | - | 3/4" Wrench |

| F9 | 2 | 1/2" Washer (Grade 8) | - | - | - |

| F10 | 2 | 1/2" ID , 1/4" Tall Cone Washer (Aluminum) | - | - | - |

| F11 | 1 | 1/2"-20 Nyloc (AN) | - | ??? | 3/4" Socket |

*Note that the Steering Arm (A) is threaded and that a washer and lock nut is used as well. The first 1-3/4" of the (F1) screws should be coated with anti-seize and torqued. Any anti-sieze that is on the threads sticking out of the bottom for the Steering Arm (A) should be removed with acetone. The washers and nylocs should then be added and torqued.

Bottoms are 1” long!!!!