I’ve removed/installed the cage many times and it’s a pretty quick and easy process. However, it’s a royal pain in the ass to install the rod ends that connect the rear legs to the top of the rear hoop. It takes me longer to install those two bolts, than it does to install the other 14 bolts combined. The issue is that the standard RCR suspension bracket is utilized which requires a high-misalignment rod end, two aluminum misalignment washers and a grade-8 washer to be crammed at an awkward angle. In fact, the body of one of my rod ends actually binds on the bracket. It’s difficult to get the washers and misalignment washers in place, let alone properly aligned, and if they fall you need to find them all because one might be in the supercharger, accessory or dry sump belt. Sometimes one hits the floor and rolls to God knows where and you can spend a lot of time looking for it on the floor or on the front engine dress. Last thing you want is foreign-object damage when you start the engine.

Conceptually this isn’t problem because the rear legs aren’t removed very often once the car is finished and you want everything tight.

HOWEVER, as can be seen in the picture below, the body significantly overhands the rod ends and it’s somewhere between a nightmare and impossible to install things when the body is on. I struggle to install the rod ends and washers when the body is removed, I’m standing in the center of the cockpit and have prefect access to everything. With the body on, it would be easy to get the rod end installed, but the misalignment washers and grade 8 washer — NFW.

The carboard simulates the body. Note how far it overhangs the rod end

Given that I must remove the rear hoop legs to remove the engine and removing the body requires removing the doors, headliner, windshield (which I risk cracking) and removing and then reinstalling all of the sealing around the foot box, side pods and firewall, this is an untenable situation.

I considered welding a section of tube to a plate mounted to the firewall and using interlocking tube couplers to enable a section of the leg to be easily removed. The issue with that approach is that the tubes welded to the firewall would need to extend an inch or so past the body which, as shown above, extends well into the engine compartment and, at least in my case, would cause them to interfere with the supercharger during engine removal.

I settled on a three-part solution:

Replace the 90-degree bracket with a custom bracket that matches the downward angle of the rear leg. This solves the root of the problem.

Replace the 1/2” right-hand-thread (RHT) high-misalignment rod end, misalignment washers and grade-8 washer with a 3/4” RHT slot clevis. This is more robust, has three less parts to drop and there is zero struggle to line things up.

Make the leg indexable by sectioning it and welding two 3/4” left-hand-thread (LHT) tube ends and a floating 3/4” grade-8 threaded rod. This makes it even easier to install/remove the leg and enables me to apply the perfect amount of preload.

The first step was to cut the tube a few inches from the Y-joint in a horizontal bandsaw to ensure a clean, square cut. I then cut the rod end off of the other end.

Rear hoop leg being sectioned with a horizontal bandsaw… no going back now!

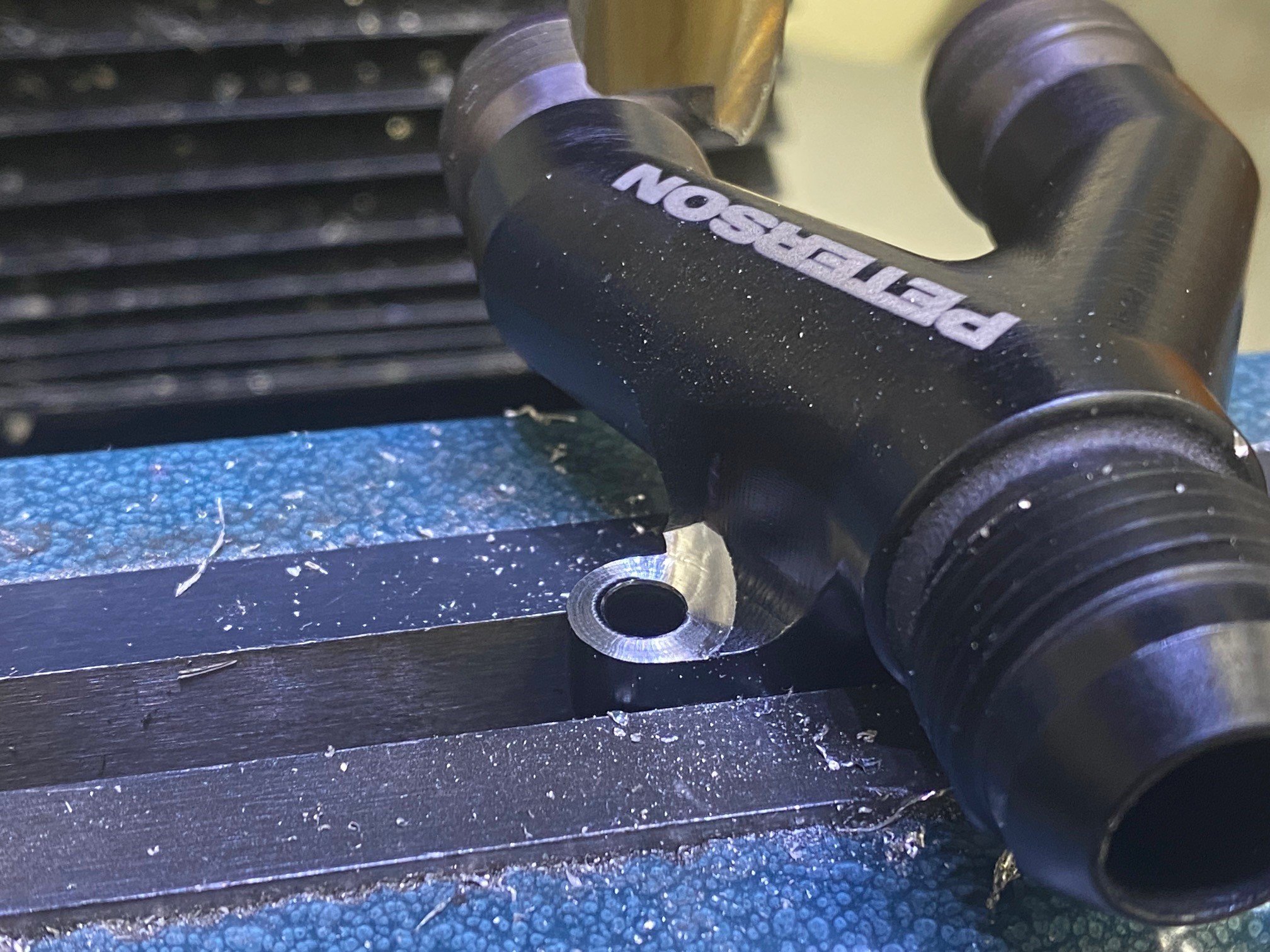

I used high-quality 4130 tube ends. They project ~2.5x further into the tube than the stock pieces which provides more thread engagement and improved resistance to lateral loads. Abe showed me a fabrication technique that he learned during his days building high-HP drag chassis. He would bore four holes in the tube 90 degrees apart to add rosette welds in addition to the standard circumference/edge weld. While this increases the amount of weld contact, the primary purpose is to reduce lateral stresses on the edge weld by anchoring the inserted portion of the tube end to the tube. A center-cutting end mill works much better than a drill bit when creating a hole on a radius.

The bracket was a bit tricky to fabricate. Given the material thicknesses and size of the parts, I only designed a single slot and tab. The challenge was that the clevis plate is angled at 60 degrees which required the edge that mates with the base plate and the matching slot in the base plate to be beveled at 60 degrees. To accomplish this, I purchased an inexpensive (about $85) tilting vice. It’s not intended for milling, but I took very light cuts and it worked well. To reduce the size of the bracket the outside gusset was angled which required some grinding of the clevis and base plates.

The clevis plate is 3/8” (that’s what the slot clevis requires), the base plate is 1/4” (I didn’t want it to warp while welding the thick clevis plate), and the gussets are 0.190”, all of which were laser cut. The slot isn’t pretty because I wasn’t going for style points when filing the corners and the fit up was good for welding purposes.

The edge of the angled clevis plate being milled at 60 degrees (the 30 degrees indicated on the vice is the reverse angle)

The upper and lower edges of the laser-cut slot in base plate about to be milled at 60 degrees (the 30 degrees indicated on the vice is the reverse angle). The end mill left rounded corners which were manually filed square.

To ensure that everything was aligned the tube ends were welded, the link was installed, the base plate was mounted to the firewall, the clevis plate was bolted to the clevis and a small amount of compression preload we applied (i.e., the link pushing the clevis plate into the base plate). A couple of clamps were added and the bracket was heavily tacked. After the bracket cooled, welding was completed on the bench.

Stock leg (left) and modified leg (right). 3/4”-16 RHT slot clevis at the top and matching LHT tube ends and floating grade 8 threaded rod at the bottom.

Wow it’s easy to install/deinstall the rear hoop legs. Nothing dropped, no profanity and to top it off I can set the perfect amount of preload. I’m very happy with this modification.

The next step is to finish the left side.