Maintenance — Serpentine Systems

The M10 x 1.5mm holes in the engine block and heads are 20mm deep.

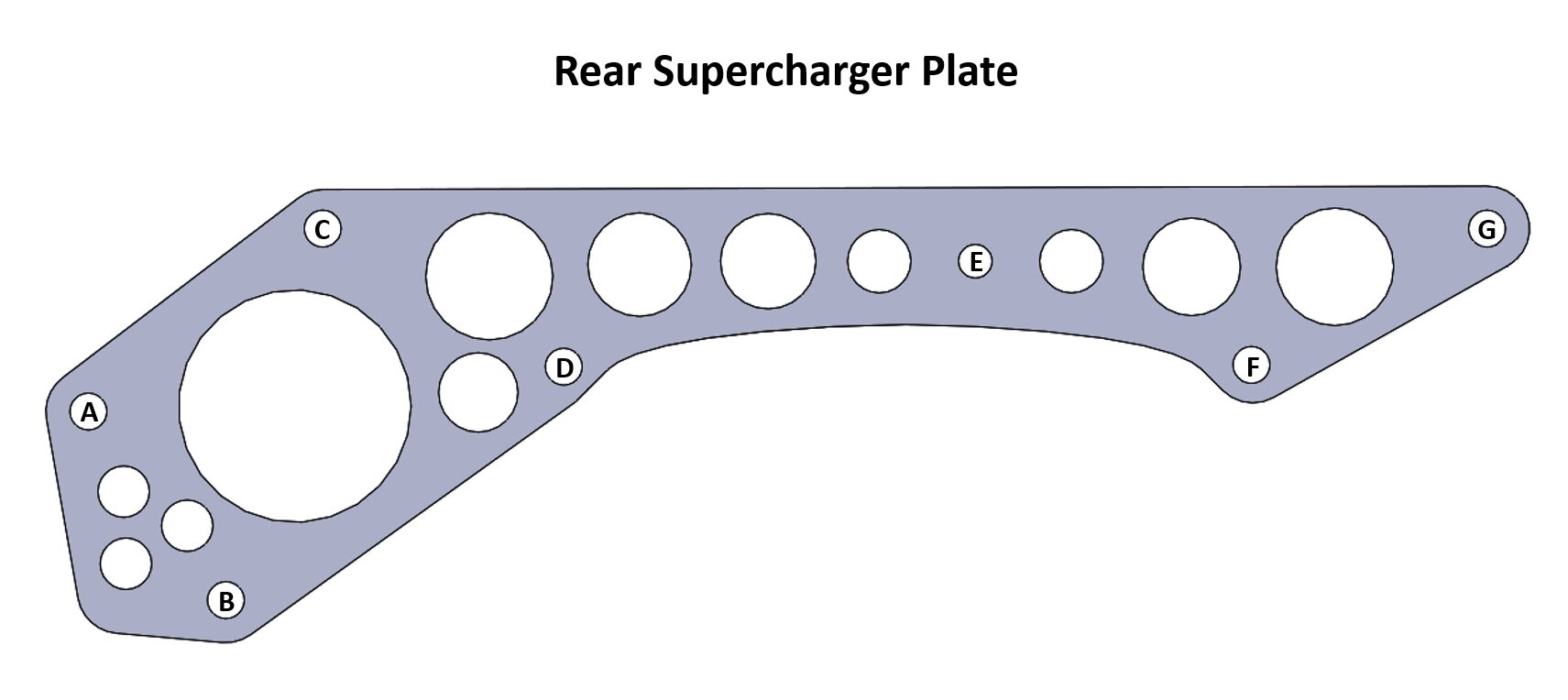

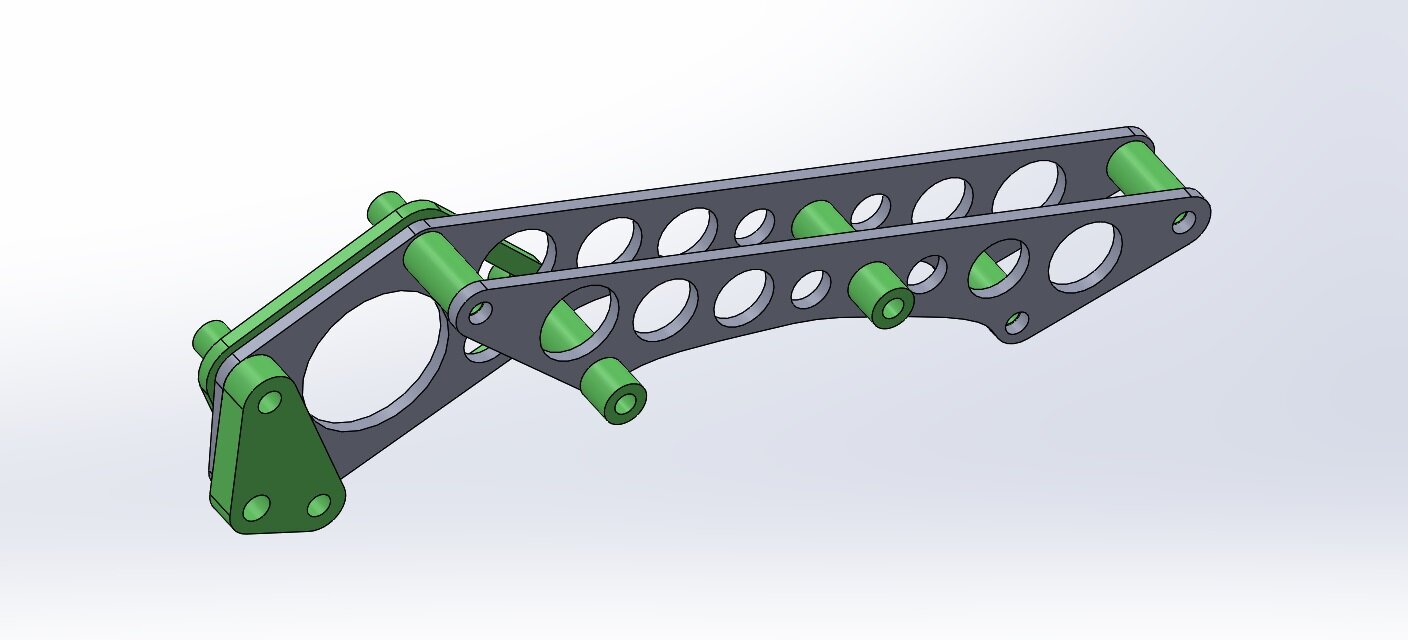

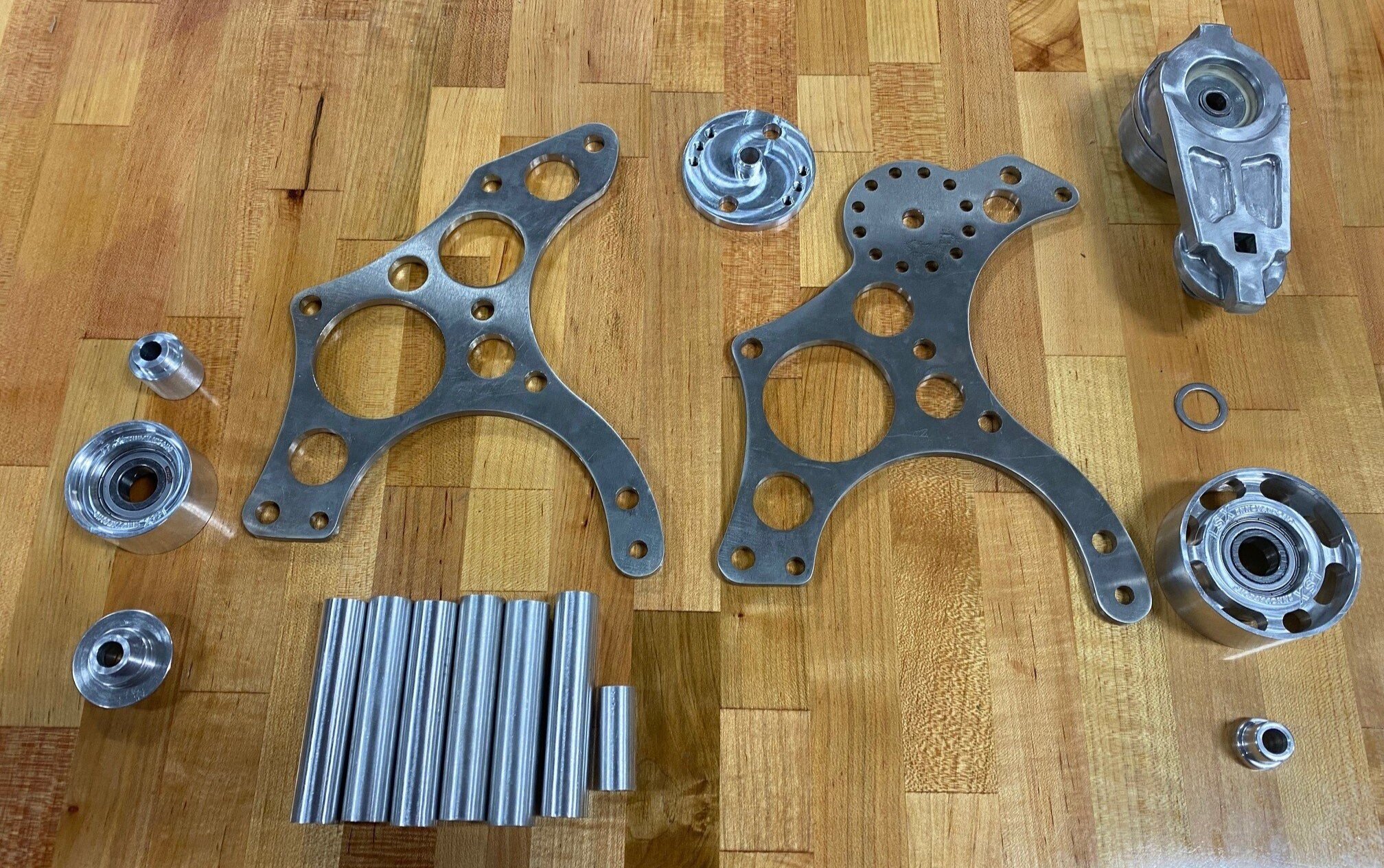

Supercharger Serpentine

| ID | Thread | Length | Block Spacer | Rear Plate Spacer | Front Plate Spacer |

|---|---|---|---|---|---|

| A | M10 x 1.5 mm | 65mm | Welded | Machined | n/a |

| B | M10 x 1.5 mm | 110mm | Welded | Machined | n/a |

| C | M10 x 1.5 mm | 110mm | Welded | 20mm x 3.650" | n/a |

| D | M10 x 1.5 mm | 160mm | Welded | 20mm x 3.650" | TBD |

| E | M10 x 1.5 mm | 135mm | n/a | 20mm x 3.650" | 20mm x 0.560" |

| F | M10 x 1.5 mm | 85mm | n/a | 20mm x 3.650" | n/a |

| G | M10 x 1.5 mm | 130mm | n/a | 20mm x 3.650" | n/a |

Gates MICRO-V K100658HD, 10PJ1672; 10-Rib 66-3/8” OC

Start with C &G

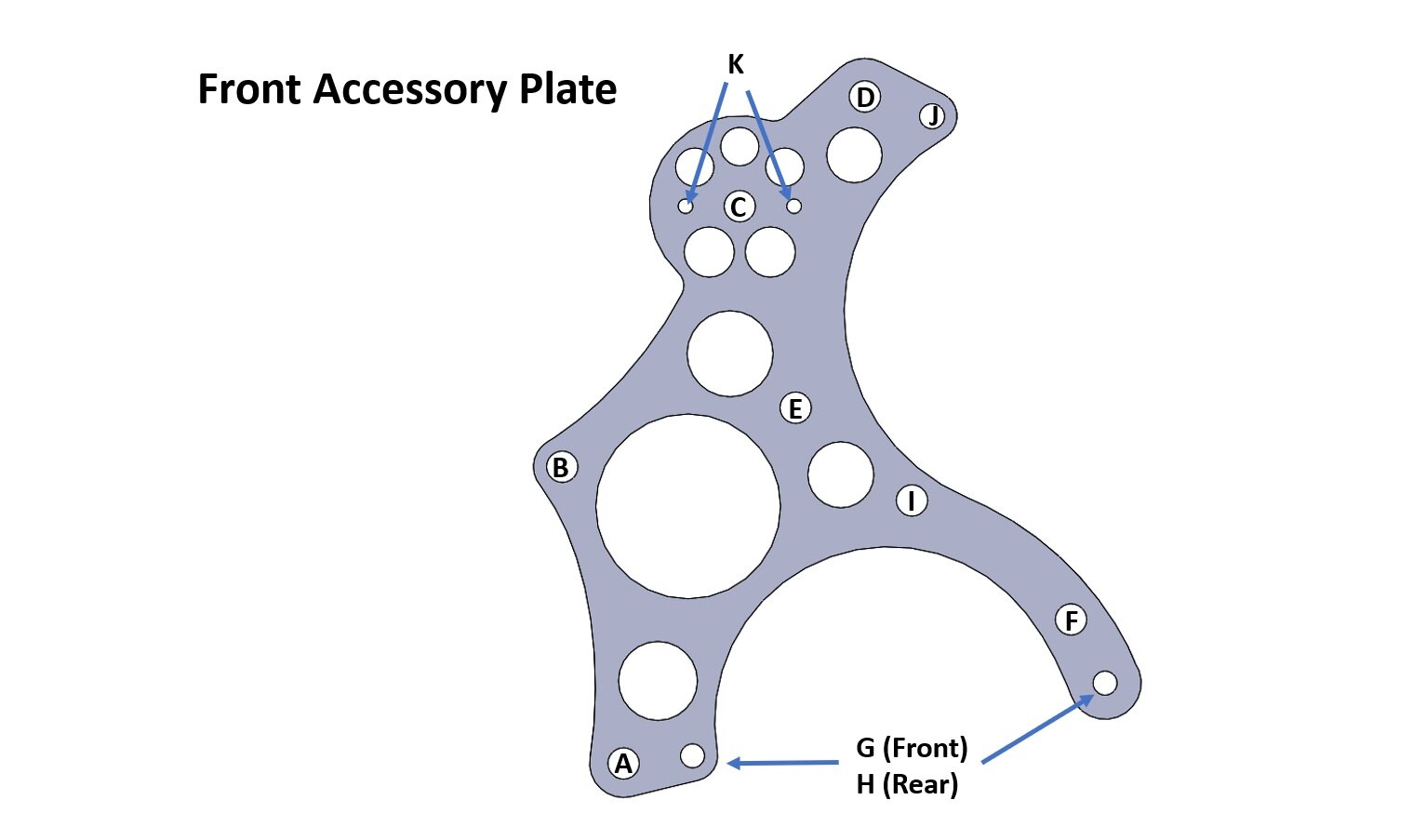

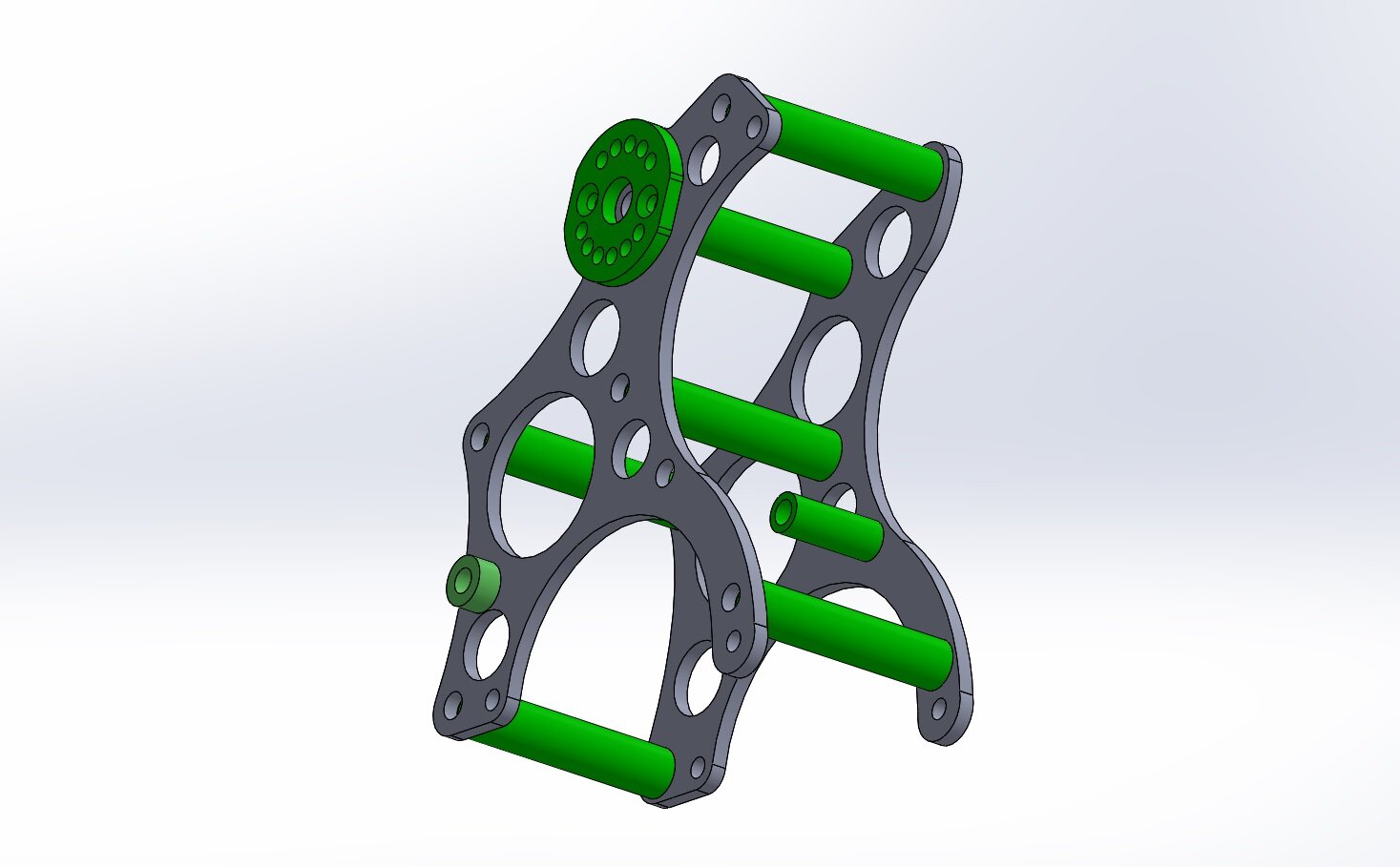

Accessory Serpentine

| ID | Qty. | Thread | Length | Rear Plate Spacer | Front Plate Spacer | Notes | Device |

|---|---|---|---|---|---|---|---|

| A | 1 | M10 x 1.5 mm | 180 mm | 20mm x 3.650" | 0.940" plus shoulder | ?" Pulley | |

| B | 1 | M10 x 1.5 mm | 110 mm | 20mm x 3.650" | n/a | n/a | |

| C | 1 | M10 x 1.5 mm | 170 mm | 20mm x 3.650" | 0.25" | Tensioner | |

| D | 1 | M10 x 1.5 mm | 130 mm | 20mm x 3.650" | n/a | n/a | |

| E | 1 | M10 x 1.5 mm | 120 mm | 20mm x 3.650" | n/a | n/a | |

| F | 1 | M10 x 1.5 mm | 120 mm | 20mm x 3.650" | n/a | n/a | |

| G | 2 | M8 x 1.25 mm | 25 mm | n/a | n/a | A/C Compressor | |

| H | 2 | M8 x 1.25 mm | 35 mm | n/a | n/a | Nyloc | A/C Compressor |

| I | 1 | M10 x 1.5 mm | 120 mm | 16 mm x 1.650" | n/a | Nyloc | Alternator |

| J | 1 | M8 x 1.25 mm | 25 mm | n/a | n/a | Alternator | |

| K | 2 | 1/4"-20 | 1/2" | n/a | n/a | Tensioner |

Belt: Bando 6PK1170

Tensioner: ACDelco 38323; replaced plastic OEM pulley with a larger 3” billet pulley, added a 1 mm shim between the pulley and the bracket

A/C Compressor 2x 0.020” shim (stainless steel)

With respect to tensioner mounting, the holes in the front plate are 30 degrees apart, the tapped holes in the spacer are 20 degrees apart and the anti-rotation holes are 5 degrees apart when the spacer is rotated 180 degrees.

To release the accessory tensioner, place 3/8” breaker bar in the end of the arm and apply pressure in an upward, counter clockwise direction. Ensure that it doesn’t slip out or the arm will be irreparably damaged.

BELTS

K060458HD 85550995 FLEETRUNNER MICRO-V 6 45.85” 46.418” (way too short)

K060470HD 85550618 FLEETRUNNER MICRO-V 6 47.12” 47.625” (a little too long)