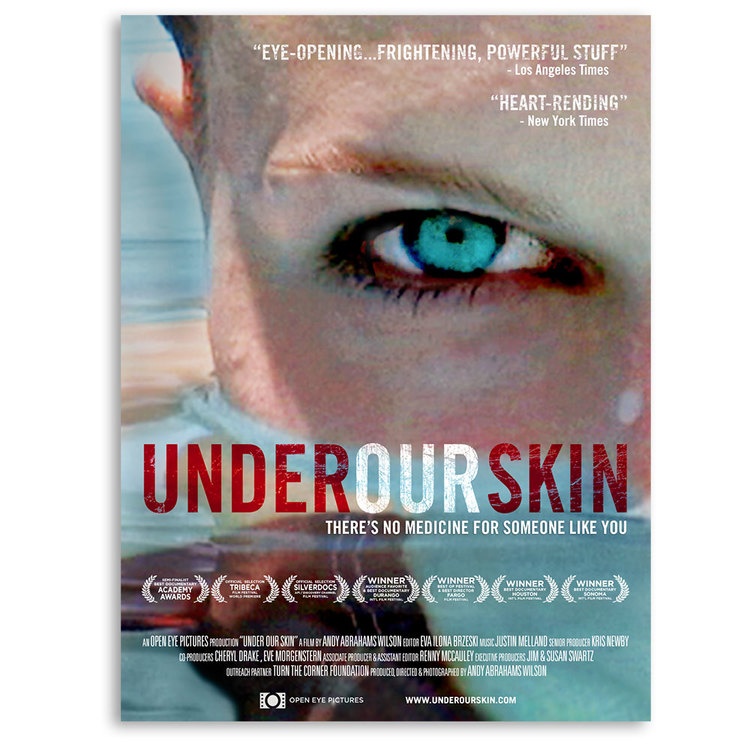

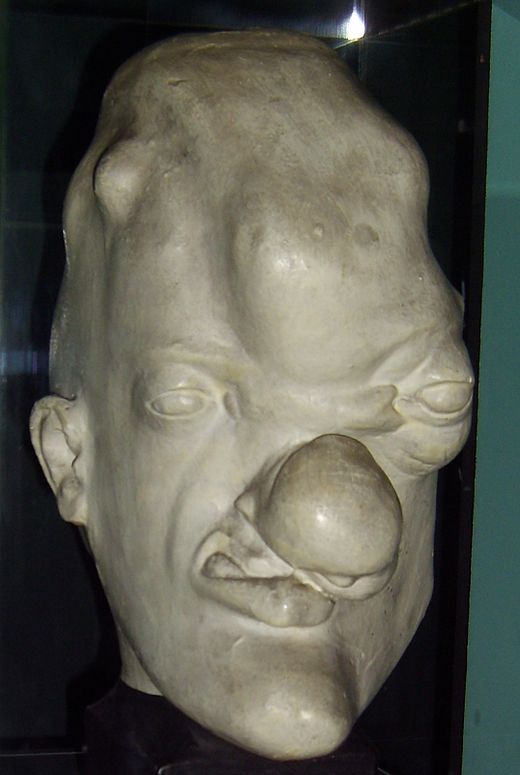

Now you may be thinking, like most USA-based doctors, that this is some treatment invented by Lyme wackos, but there is medical precedence and science behind the treatment. Firstly, everyone should understand that when you get sick your body creates a fever to cook pathogens. Secondly, Julius Wagner-Jauregg took this "fever-is-good" approach to the next level when he won the Nobel Prize in Physiology or Medicine in 1927 "for his discovery of the therapeutic value of malaria inoculation in the treatment of dementia paralytica." In short, he used the blood from a soldier with malaria to infect three of his neurosyphilis patients with malaria. The good news was that the resulting high fever killed the syphilis bacterium. The bad news was that they now had malaria.

Thirdly, according to the St. George Klinik, in vitro cultivation of Borrelia burgdorferi (B.b.) demonstrates that the spirochete replicates most quickly at 37 °C (98.6 °F) making the human body the perfect incubator. If the temperature is increased to 39°C (102.2 °F) the growth of B.b. is significantly impeded. At 41 °C (105.8 °F) all spirochetes in the culture are killed after 24 hours, whereas at 41.6 °C (106.9 °F) all spirochetes are killed after two hours. They also claim that the intravenous antibiotics are 16 times more effective at that temperature. That's the science behind the hypothermia treatment. Of course all of this makes me think of the time vs. temperature pasteurization tables that I use when cooking Sous Vide.

Unfortunately, they couldn't do the whole body hypothermia on me because of my heart, so they gave me a special local hypothermia on my head. I walked into the allotted room dragging my IV stand. The nurse swapped my clear IV bottle for a new one with nasty looking yellowish liquid...

"What's that for?", I asked.

"To keep your brain from swelling too much."

"Why do I need that?

"We're going to heat your head up."

"How hot?"

"44.5", she replied. I know that 100 is boiling, so that sounded hot, but I don't comprehend Celsius so I looked it up on my iPhone. That's 112.1 degrees Fahrenheit!!!

"Isn't that dangerous?", I asked.

"Ya, ve know what we're doing."

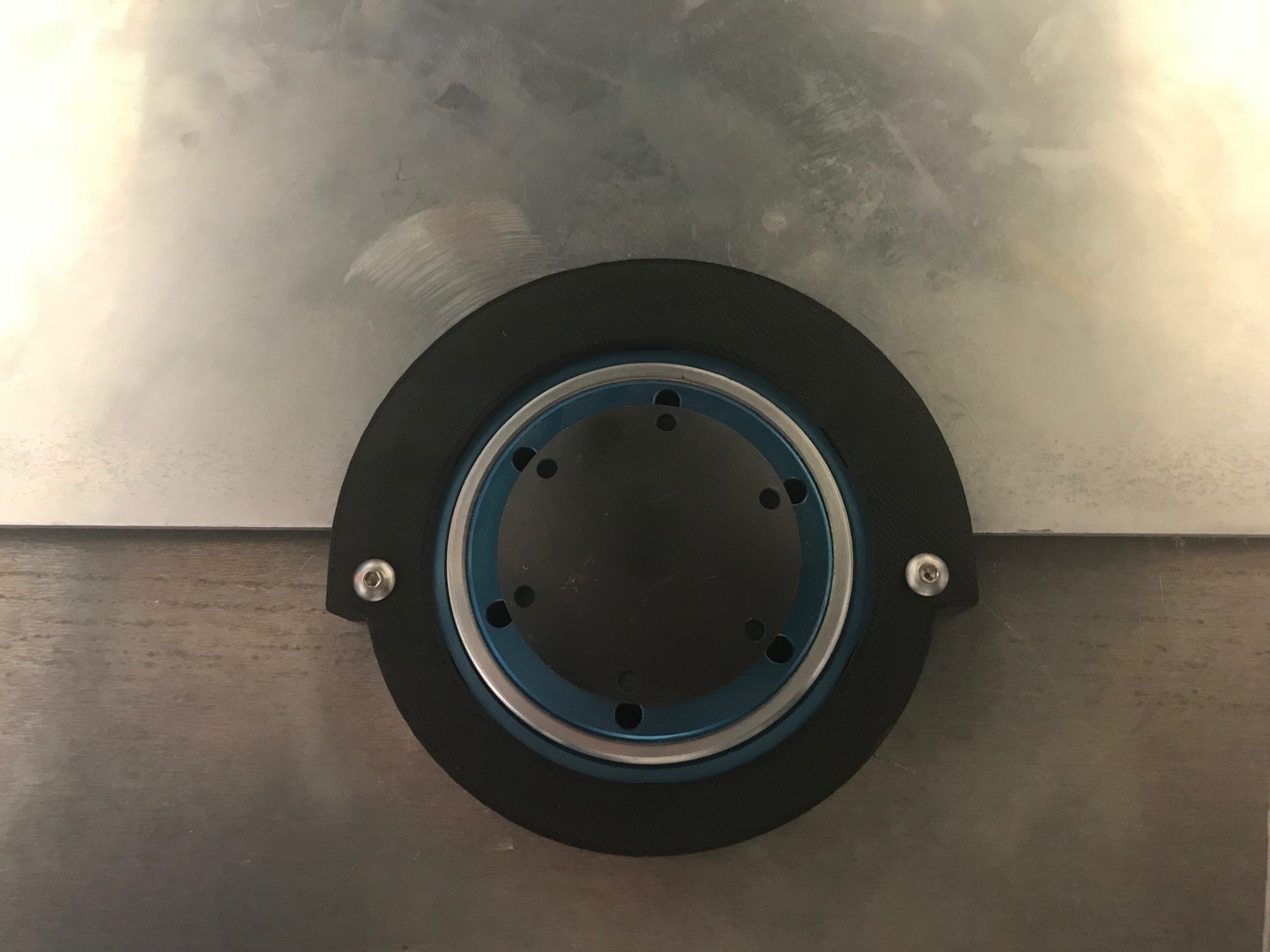

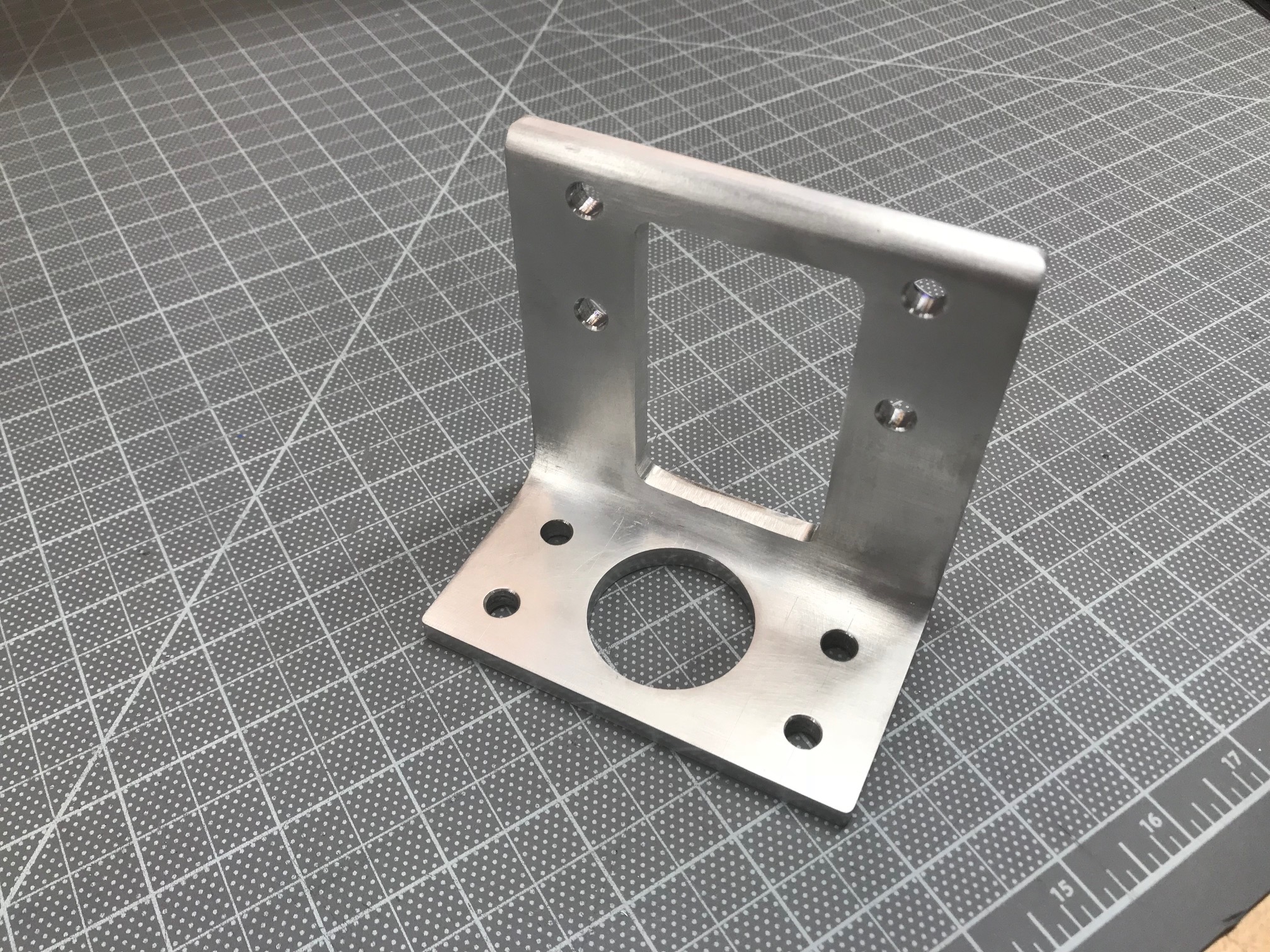

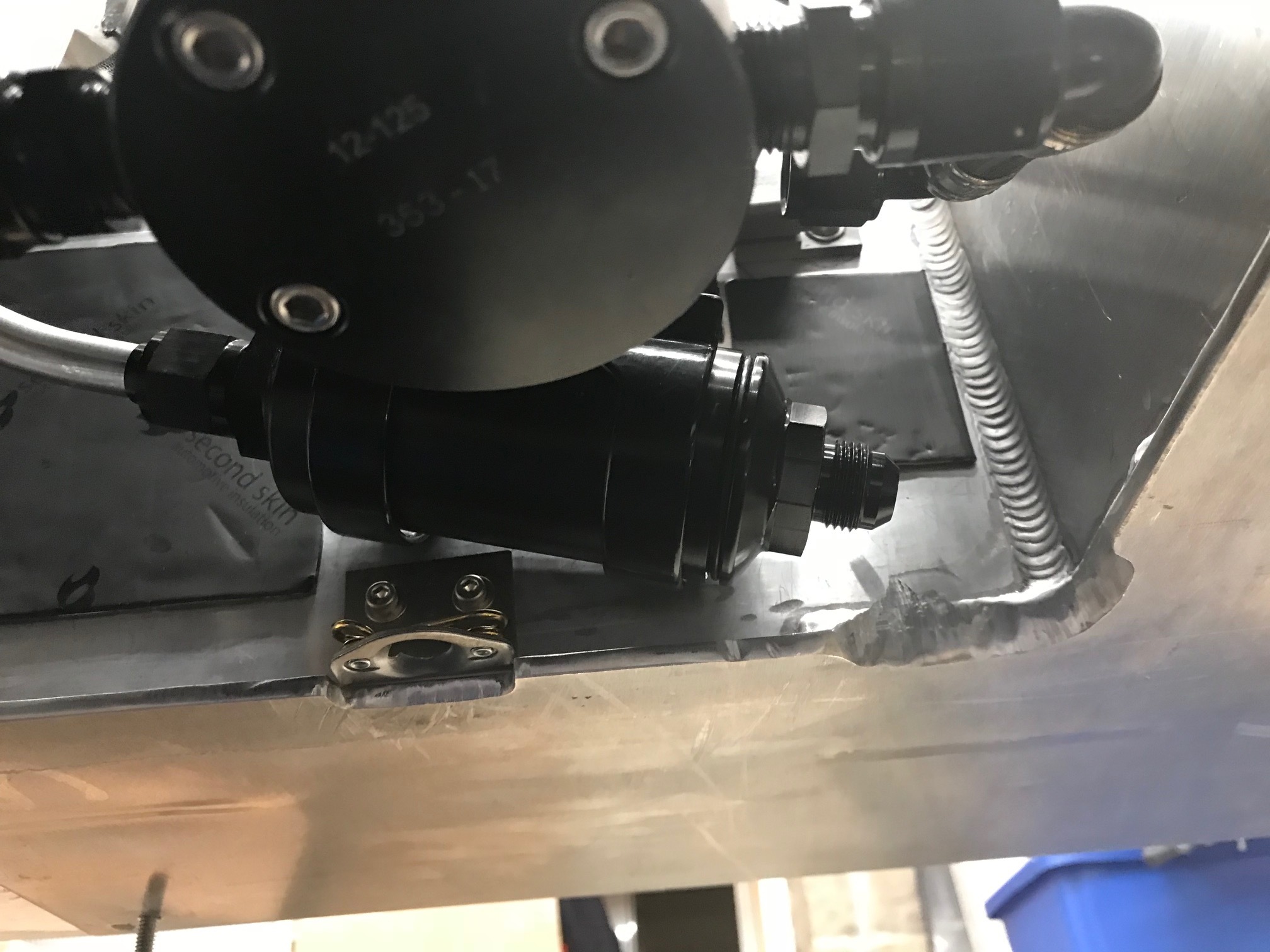

Where's that calming gel? This has to be easier that getting three shots to the eye, right? There was a machine about as tall as I am with lots of buttons, dials and LED readouts and cables that led to an articulated arm hanging over the table. It looked like something from the set of The Six Million Dollar Man - high tech, but dated (not worn, just not state of the art electronics). As instructed, I took off metal items and I laid down on the table and rolled on my side. The nurse carefully positioned the business end of the arm on the back half of the side of my head such that it covered half of my ear. She then gave me a horn and told me to squeeze it if things got too hot. At first I didn't feel much, but I started to profusely sweat, especially on my head. At some point the skin directly under the contact area with the machine started to burn and then burn really bad.... "HONK!".